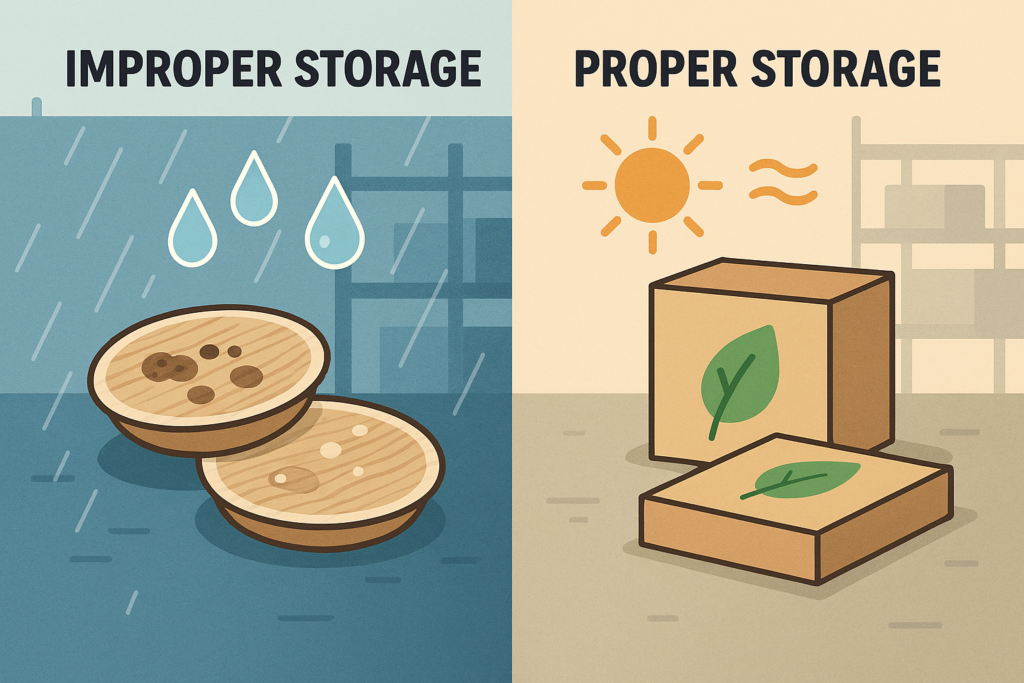

When it comes to eco-friendly dinnerware, areca leaf plates are one of the most sustainable and attractive alternatives to plastic. Lightweight, biodegradable, and naturally stylish, they are widely used for catering, restaurants, events, and home dining. But one persistent challenge for exporters and importers of areca plates is their vulnerability to fungus during the rainy season or when stored in high-humidity conditions.

At R2S GREENWAVE, we specialize in manufacturing and exporting premium areca leaf dinnerware that meets international standards. Over the years, we’ve seen how humidity, improper storage, and poor packaging can reduce shelf life. In this blog, we’ll share insights on how importers prevent fungus in areca plates during the rainy season, along with proven storage and packaging tips to keep your products fresh, safe, and market-ready.

Why Areca Leaf Plates Are Prone to Fungus in Humid Conditions

Areca plates are made from naturally shed palm leaves, which are pressed into shape without chemicals or coatings. While this makes them 100% biodegradable and compostable, it also means they can absorb moisture from the environment.

During the rainy season or in coastal humid climates (such as Dubai, Jeddah, Dammam, and Muscat), the combination of heat and moisture creates a perfect environment for mold and fungal growth. Even when plates are safe for food use, visible mold spots or warping can lead to customer rejection.

That’s why humidity control and fungus prevention are critical at every stage—from manufacturing in India to storage by Gulf importers.

Preventive Measures at the Manufacturing Stage

- Proper Drying: At R2S GREENWAVE, plates undergo sun-drying and hot-air oven drying to reduce moisture content below 12%. This significantly minimizes fungal risk.

- UV or Steam Sterilization: To kill surface microbes, some exporters apply UV light or steam treatment before packing.

- Strict Quality Sorting: Plates with cracks, excess fiber, or uneven drying are removed because they are more prone to mold during storage.

By ensuring plates leave the factory with low moisture content, we set the foundation for safe long-term storage.

📦 Packaging Tips for Rainy Season Exports

Importers often emphasize that packaging is as important as production. Here’s how moisture is controlled during transit:

- Vacuum sealing or shrink-wrapping: Keeps plates airtight and moisture-free.

- Silica gel or desiccant sachets: Absorbs excess humidity inside cartons.

- Poly-lined cartons: Double-layered or laminated cartons resist moisture penetration during shipping.

- Fumigated containers with desiccant poles: Prevent container sweat (condensation) during long sea voyages.

At R2S GREENWAVE, we customize packaging solutions for buyers depending on their destination climate. Gulf importers, in particular, prefer poly-wrapped cartons with desiccants because of high summer humidity.